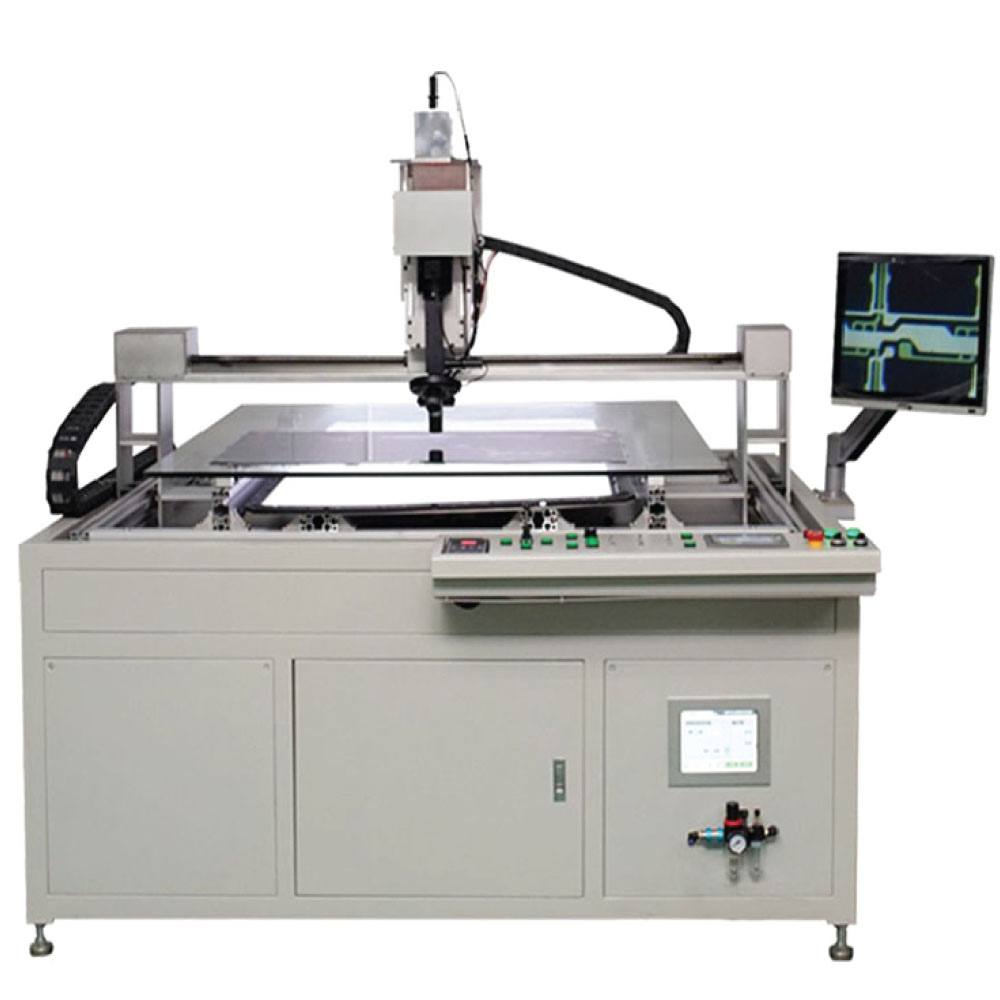

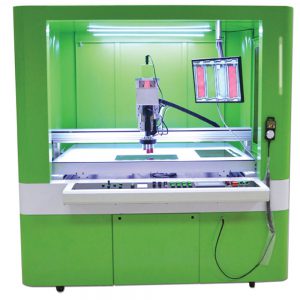

MD-512DH LCD Screen Laser Repair Machine 80

Laser machine have 4 Models:

- MD-512S: 26” – Suitable for laptop, mobile phone screen repair

- MD-512A: 50” – Suitable for small size TV screen repair

- MD-512D: 80” -Suitable for big size TV screen repair, Split machine

- MD-512DH: 80” – Suitable for big size TV screen repair, Integrated machine

Machine Description:

This specification is about electronic automation and laser produces TFT-LCD panel design of the system for repair. The device is equipped control system from research and development (including Laser Head?HOYA Laser Controller)?using MITUTOYO precision optical imaging system (laser processing / observing special microscope?laser processing special optical lens?image observation objective lens)?X / Y / Z motor drive system? Electronic control systems?Gas pressure cushioning system?Composed of precision steel base and other .This equipment can be given workpiece material layer for short-circuit defect repair process. Workpiece to use manual mode .

Main purpose:

LCD laser repair machine (referred to as laser machine) on the LCD screen repair industry accounted for the high-end repair technology, the most high-end technology of LCD screen repair ,LCD screen repair industry in addition to the COF loose welding, TAB char (This error can be repaired with a binding machine) Others such as ITO break, short line, bright line, half-line, dotted line ,a multi-line laser machine can be used to repair. Laser machine with high efficiency, fixed rate, low cost (the same fault in the laser machine does not need replacement parts, (and do not affect the repair rate), it is widely used as the main device screen repair of large-scale production factory?after sale and service company.

Laser repair purposes, is hoping to further the defective part to be corrected, so that the original filter out waste products to be discarded, repair to an acceptable product. The current acceptable product standards—-Firstly is definitely not wired defects; secondly, many products are “no highlights assurance”. Secondly, many products are “no highlights assurance” ,so the pixel can not have been glowing are bright spots ,but to some extent accepted few dark spots. Therefore, the object of laser repair, based on the main line defect and highlights.

The way of laser repair :Welding—- In the two story metal overlap over the place, in appropriate energy and wavelength of the laser can be metalized open and welded together, let the two originally not connected electrodes connected (and cut off to achieve disconnect)to repair.